Steel Form Work Climbing System Formwork

1. The lateral pressure of the concrete is entirely supported by the anchor system, wall-through tie-rods are not needed. The finished concrete surface is perfect.

2. The formwork can move backward entirety, which will be convenient for work.

3.Coupling is used for connecting the neighbouring forms to make sure the forms standing in a beeline.

4.The connecting components have a high standardization and versatility.

5.The formwork can prop to the finished concrete tightly to avoid offset or leakage.

6.The formwork can be adjusted horizontally or vertically as request.

7.DP-180 system can be adjusted forward and backward. The Max. angle is 30°.

1. The first pouring

1. The first pouring

The lateral pressure is supported by bottom beam anchor system during the first concrete pouring.Embed wall anchor system which will be the most important supporting parts during the next pouring.

2.The second pouring(the first lift)

The climbing brackets are used in the second pouring, which are fixed on the anchor system in the finished wall.

3. The third pouring(the second lift)

Fix the suspend platform under the whole system, the workers can remove the tensile bolt and V- climbing cone on the platform and then fill the holes left by the V-climbing cone. The later lifts are standard same as the second lift until the concreting is finished.

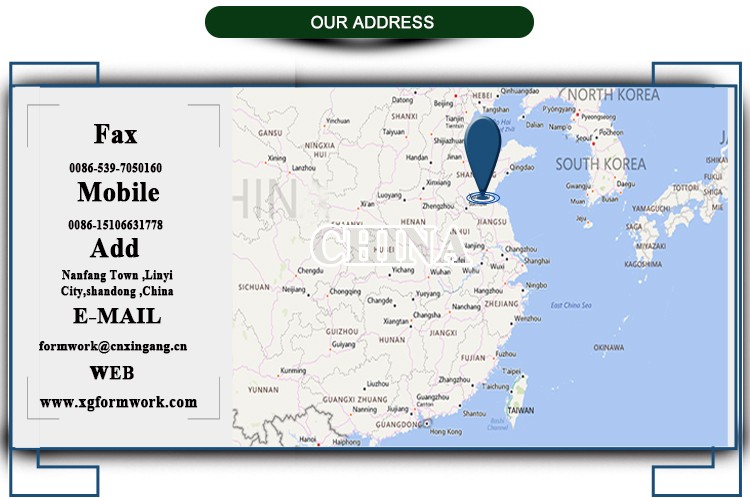

1. Consultancy

Offer you a general idea about formwork & scaffolding

2. Technical Planning

Customized forming & shoring solution proposal according to your structural drawing by Auto-cad

3. Logistics

Fast to your site with proper packages & well organized loadings

4. On-site supervision

Shop drawing, assembly drawing, and even send our supervisor to your site for training and supervision

1. Why Choose Us? |

We are a more than 10 years professional manufacturer in formwork with high quality and competitive price. |

2. What's your auto fastener guarantee? |

Strictly complying with quality management systems of ISO 9001 and SGS. If you have any problems concerning quality, we will offer you a refund or a replacement. |

3. How long is the date of delivery? |

If inventory goods, we will delivery within 7 working days. For a customized order, within 20 days. |

We can make plan of everything needed according to the project's structural drawing in Automated format or blueprint. In the CAD design, it clearly shows how to install every item with exact quantity.

|